Why Data Should Guide Cannabis Automation Investments

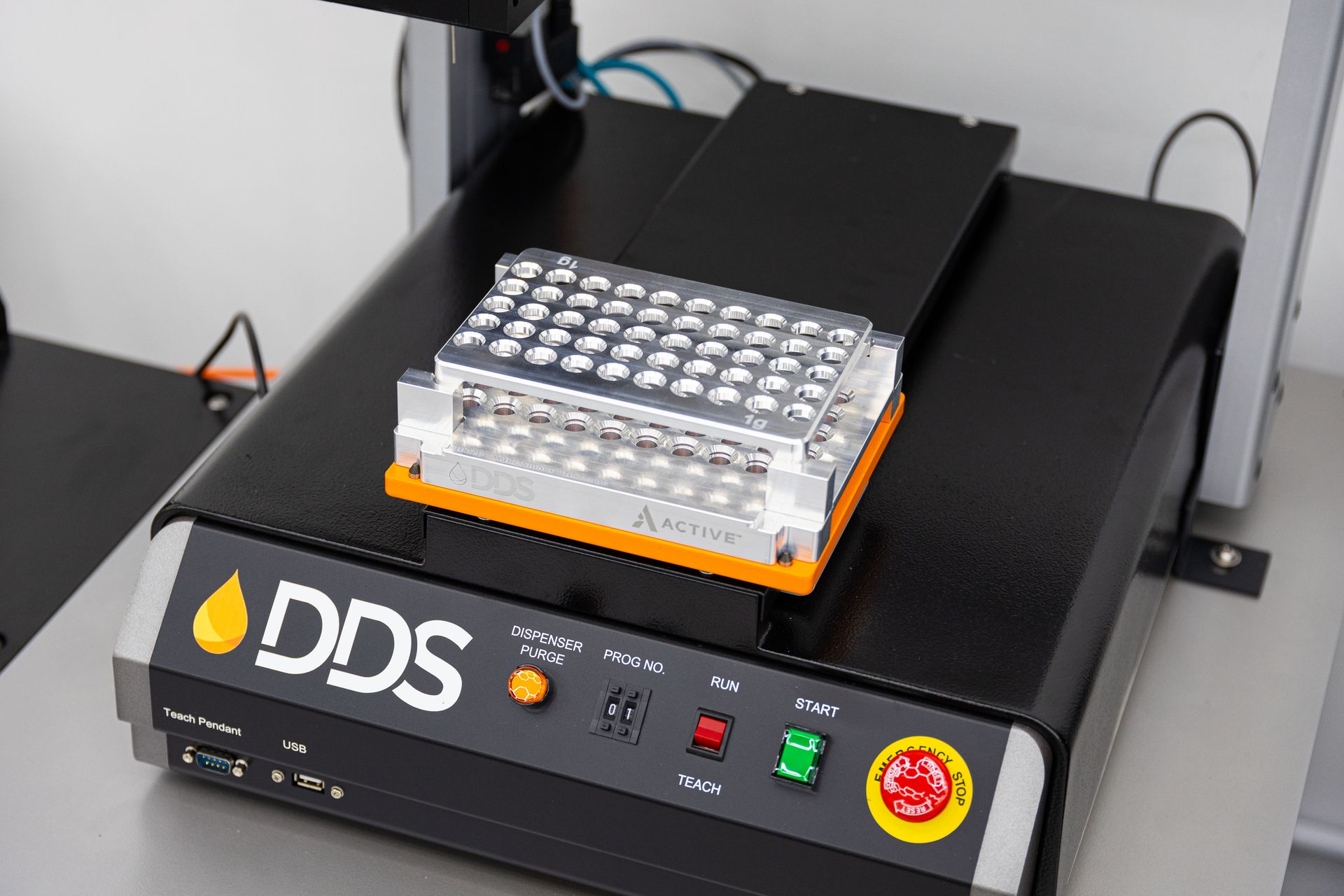

Consistency. Throughput. Product integrity. These are the pillars of any successful vape operation. But when it comes to filling cartridges at scale, even small missteps can ripple into bigger problems: lost product, slower production, or worse, failed compliance tests. That’s why more producers are turning to precision-built tools like the CFM-1800, Detroit Dispensing Solutions’ flagship cartridge filling machine, to eliminate avoidable errors and streamline operations. Let’s take a closer look at the most common mistakes made during vape cartridge filling and how the right equipment can prevent them.

Relying on Manual Filling in a High-Volume Environment

Some operations still depend on manual methods, even while scaling. While this might work for limited SKUs or small batches, it quickly breaks down under higher demand. Manual filling is time-consuming, inconsistent, and often leads to product waste. The real issue is repeatability.

An automatic cartridge filling machine like the CFM-1800 delivers measurable gains here. Designed to produce over 1,800 cartridges per hour, it reduces labor costs while improving dosing accuracy. Automation means giving people the tools to focus on quality control instead of repetitive manual labor.

Using the Wrong Equipment for the Material

Not all filling machines are made to handle the unique demands of cannabis oils. Standard systems designed for thinner substances or pharmaceuticals may struggle with live resins, rosins, or distillates. This often results in uneven fills, clogs, or excess heat exposure that damages terpenes. The CFM-1800 was engineered from the ground up for cannabis. Its custom-designed, positive displacement valve handles even high-viscosity oils with precision and without thermal degradation. When you use a cartridge filling machine built for the job, there’s less room for error and more room for consistency.

Overheating or Underheating Your Product

Getting oil to the right temperature is a balancing act. Too cool, and you risk clogging or misfiring during fills. Too hot, and you start burning off terpenes and cannabinoids. Either way, the end result is compromised product quality.

This is where temperature control systems matter. The CFM-1800 maintains a stable distillate temperature around 50°C, ideal for both distillates and live resins. With real-time temperature monitoring and uniform thermal distribution, it ensures the material flows smoothly without damaging the final product.

Letting Maintenance Interrupt Production

Downtime hurts. Unfortunately, many operations don’t prioritize machine maintenance until something breaks. When your equipment isn’t modular or built with accessibility in mind, even a minor repair can take hours. With the CFM-1800, Detroit Dispensing Solutions focused on long-term uptime. Its modular components allow for fast swaps and simple servicing, meaning your team spends less time troubleshooting and more time producing. The best cartridge filling machine also minimizes disruption when something goes wrong.

Overlooking the Big Picture

Most of these issues have one thing in common: they stem from using equipment that isn’t built for cannabis, or not built for scale. Automation can’t fix everything, but it does provide a foundation for cleaner, faster, and more consistent production.

When you invest in an automatic cartridge filling machine you’re building a process that supports future growth. Whether you’re launching a new product or expanding your output, choosing the best cartridge filling machine makes it easier to meet quality standards and stay competitive.

Looking to improve your cartridge filling operation? The CFM-1800 from Detroit Dispensing Solutions is built to help you avoid the most common pitfalls without slowing you down.

Ready to learn more about DDS' vape filler options? Contact our team for in-depth performance data and system specs.