Evolving Culture of Cannabis Vape Production

Detroit Dispensing Solutions (DDS) carries a focus on shifting the cannabis vape production landscape. We lead the sector with automation solutions for cannabis cartridge manufacturing that transform the efficiency, clarity, and scalability of cannabis businesses, empowering our clients to achieve unparalleled success and maintain a competitive streak.

Cannabis Industry: Trajectory Into DTC Retail

The cannabis industry has vested into a complex sector demanding strict regulatory compliance as it increasingly moves towards direct-to-consumer retail. Within this landscape, automated vape cartridge production is an integral aspect where consistent quality and scalable output are paramount to satisfy growing consumer demand directly. This shift necessitates advanced manufacturing solutions capable of meeting stringent standards and high-volume needs.

Navigating Industry Challenges

Operators in the cannabis vape sector face several challenges that can impede growth:

- Product Consistency: Ensuring uniform fill volumes and quality control is important for brand reputation and customer satisfaction.

- Operational Efficiency: Manual processes can reduce throughput and increase labor expenses.

- Regulatory Compliance: Adhering to regulations with documentation and structured practices for the complex legal ordinances.

- Equipment Capacity: The need for cannabis concentrate dispensing systems and machinery that can handle different oil viscosities and cartridge types for a range of product lines.

At DDS, automation systems are engineered to overcome these limitations, letting clients improve their workflows.

DDS Automation Solutions: Made-to-Fit Cannabis Vape Production

Our cannabis vape automation equipment is

meticulously designed to include every facet of cannabis vape cartridge

filling. By integrating these, businesses can foresee significant

improvements in efficiency, accuracy, and compliance.

High Throughput

Capable of filling and capping up to 1,800 cartridges per hour, facilitating large-scale operations.

Precision Filling

Utilizes a true-rod positive displacement valve, ensuring fill accuracy

within ±1%, accommodating both distillates and live resins.

Low-Temperature Operation

Dispenses materials at temperatures as low as 40°C, preserving the integrity of heat-sensitive extracts.

Clean-In-Place (CIP) Technology

Automates cleaning, reducing production time and maintaining purity.

User-Friendly Interface

Features a touchscreen control panel for rapid operation and real-time monitoring.

For more details, visit our CFM-1800 product page.

Compact Design

Makes the same filling capabilities possible as the CFM-1800 but without the capping press, ideal for facilities with limited space.

Versatile Filling

Handles various oil viscosities, ensuring consistent fills across different product lines.

Scalability

Integrates easily with existing production setups, allowing businesses to scale operations.

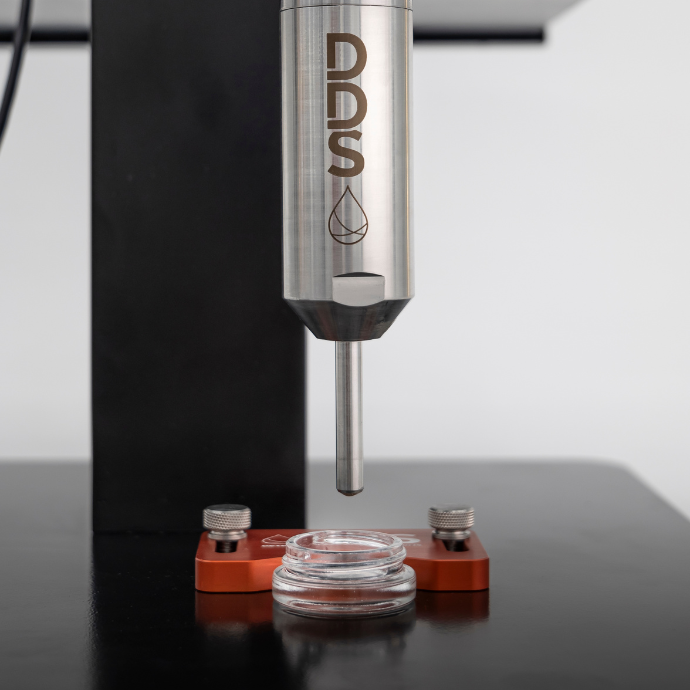

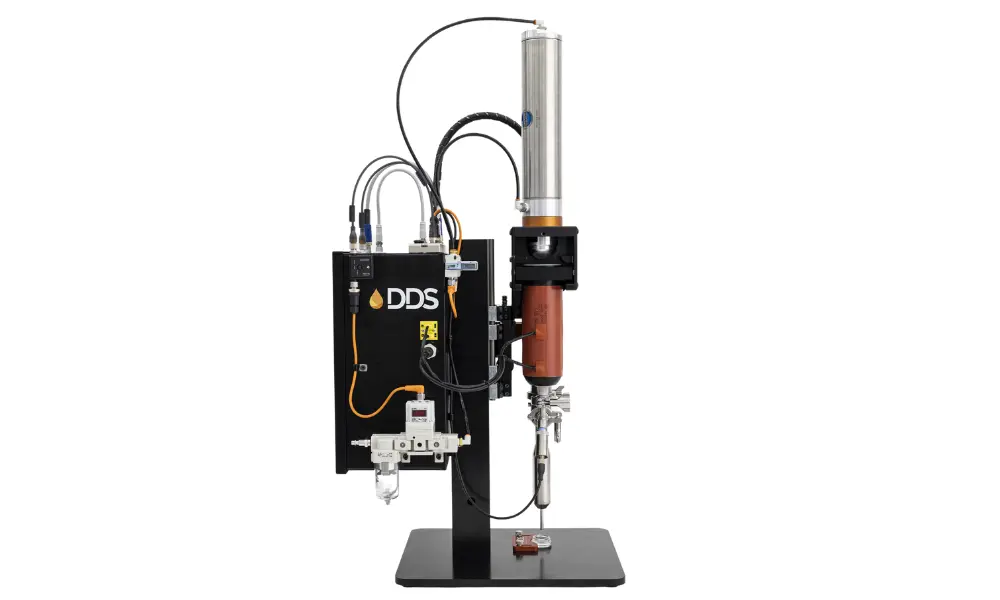

CDS-1000 Automated Concentrate Dispensing System

The CDS-1000 is a revolutionary solution for dispensing cannabis extracts into containers:

Adaptability

Efficiently dispenses a range of consistencies, including badder, butter, sauce, wax, and both live and cured resins.

Temperature Control

Operates at room temperature for most extracts, with the ability to handle more viscous materials at slightly elevated temperatures (80-85°F).

Precision Dispensing

Achieves shot accuracy up to ±1%, minimizing waste and ensuring product consistency.

Ergonomic Design

Facilitates single-operator use, increasing productivity and reducing labor costs.

Discover how the CDS-1000 can transform your cannabis concentrate packaging.

Collaborative Partnerships: Strengthening the Cannabis Ecosystem

At DDS, we believe that collaboration shines through innovation. We have established strategic partnerships with industry leaders to provide cohesive solutions that modernize cannabis production workflows. Our partners’ logos, displayed on our homepage, represent our merit.

Need Pricing? We’ve Got You Covered!

The best prices for high-performance vacuum ovens—request yours now!

Our Esteemed Partners