CFS-1800:

Cartridge Filling System

Fill up to 1,800 vape cartridges or infuse 1,500 pre-rolls per hour with ±1% dosing accuracy at industry-leading low temperatures.

CFS-1800

Cartridge Filling System

The CFS-1800 is a compact version of the CFM-1800, offering the same precision and performance in a smaller footprint—without the capping press. It automates both vape cartridge filling and pre-roll infusion, delivering up to 1,800 cartridges or 1,500 pre-rolls per hour. Equipped with a true-rod positive displacement valve engineered specifically for cannabis and a custom thermal system, the CFS-1800 ensures precise, metered dispensing of distillate and live resin at industry-leading low temperatures.

The CFS-1800 is backed by a one-year warranty and includes professional installation, training, and ongoing technical support to ensure seamless operation from day one.

Precision Automation for High‑Throughput Filling

Delivering ±1% dosing accuracy at the industry’s lowest dispensing temperatures, the CFS-1800 automates cartridge filling and pre-roll infusion for seamless, single-operator performance.

Fill 1,800 Carts/Hour

Fill up to 1,800 vape cartridges from foam or infuse up to 1,500 pre-rolls per hour with just one operator. The CFS-1800 combines speed, precision, and reliability for scalable production.

Dispense Distillate at 50°C

Operating at industry-leading low temperatures, the CFS-1800 protects your product from heat degradation. Every fill maintains consistent potency, rich flavor, and the full profile of delicate terpenes.

±1% Dosing Accuracy

Designed for cannabis, the CFS-1800 uses servo-driven precision and a pneumatic spool valve to deliver ±1% dosing accuracy, ensuring smooth, repeatable fills for every formulation.

Mitten Extracts Optimizes Vape Production with the CFS-1800

Mitten Extracts, one of Michigan’s largest and most recognized vape companies, relies on DDS’s CFS-1800 and CFM-1800 automatic cartridge filling machines to streamline their production. These precise, easy-to-use machines are tailored to their unique workflow, helping maintain quality and consistency at scale while supporting confident growth.

“With DDS, we’ve been able to scale confidently. Their machines are precise, easy to use and backed by a great team!”

—George Hallak, Co-Founder, Mitten Extracts

Advantages of the CFS-1800

Every component of the CFS-1800 is built from the ground up for cannabis, including our jig-based system and proprietary valve technology—ensuring unmatched accuracy, consistency, and reliability in every cartridge filled.

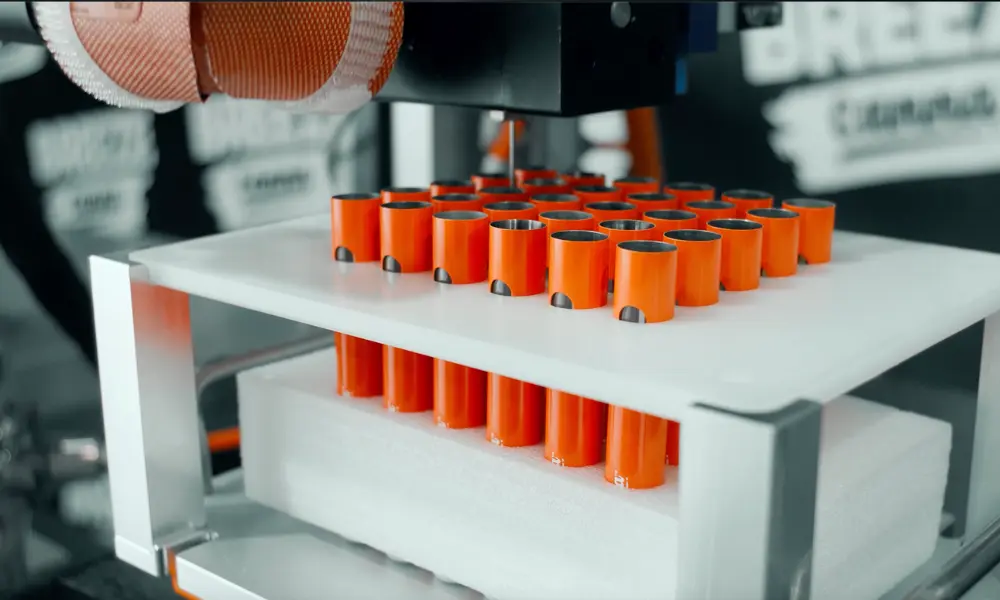

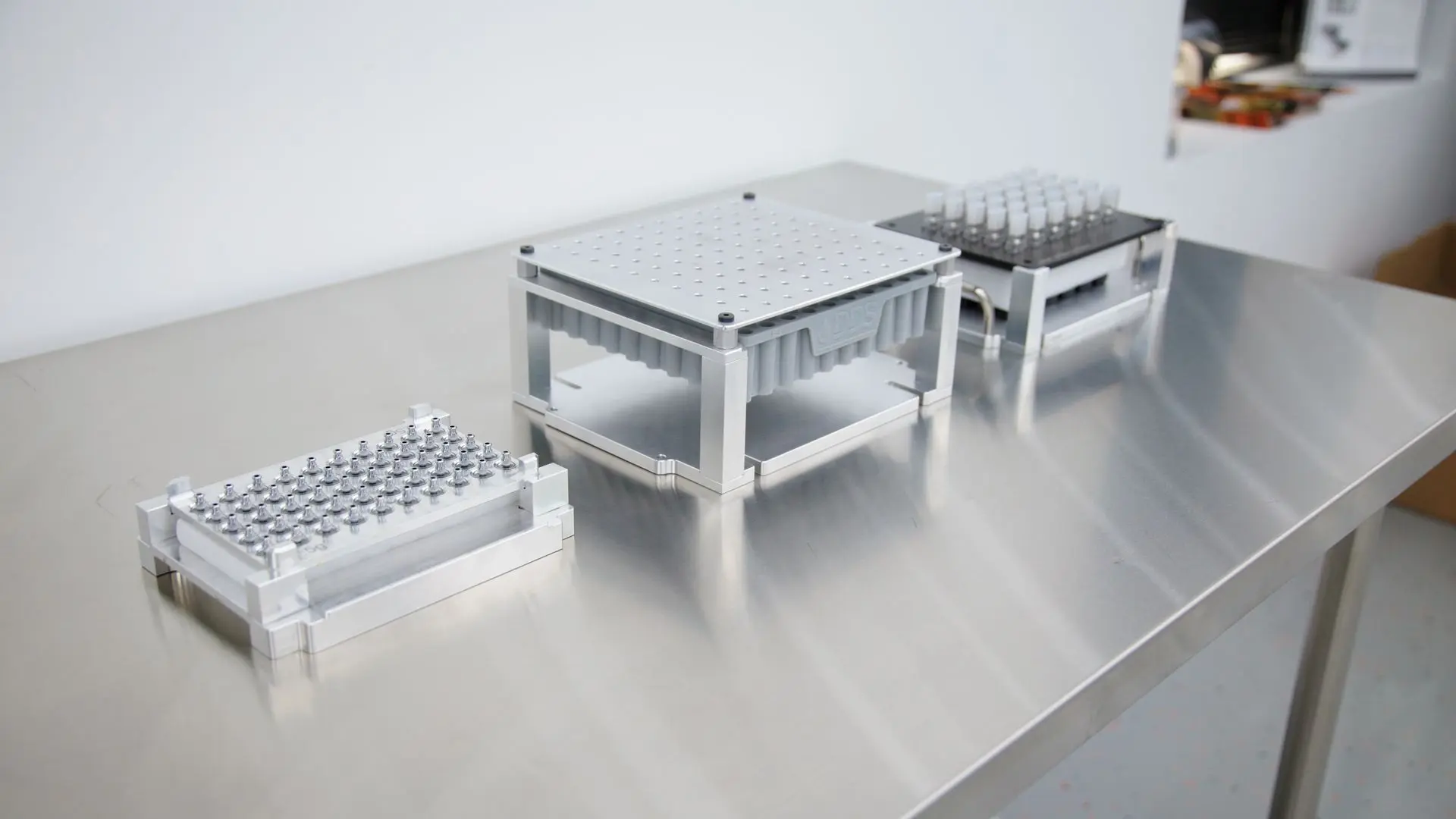

Jigs Optimize Workflow

The CFS-1800’s jig-based system adapts to cartridges, all-in-ones, pre-rolls, and syringes with fast changeovers and maximum uptime. Each jig is custom-built in-house for perfect fit, streamlined workflows, and fewer operator touchpoints—enabling faster setup, reduced errors, and consistent output. Designed for real-world efficiency, our jigs fill directly from foam packaging and cap mouthpieces in the same cycle to keep production moving.

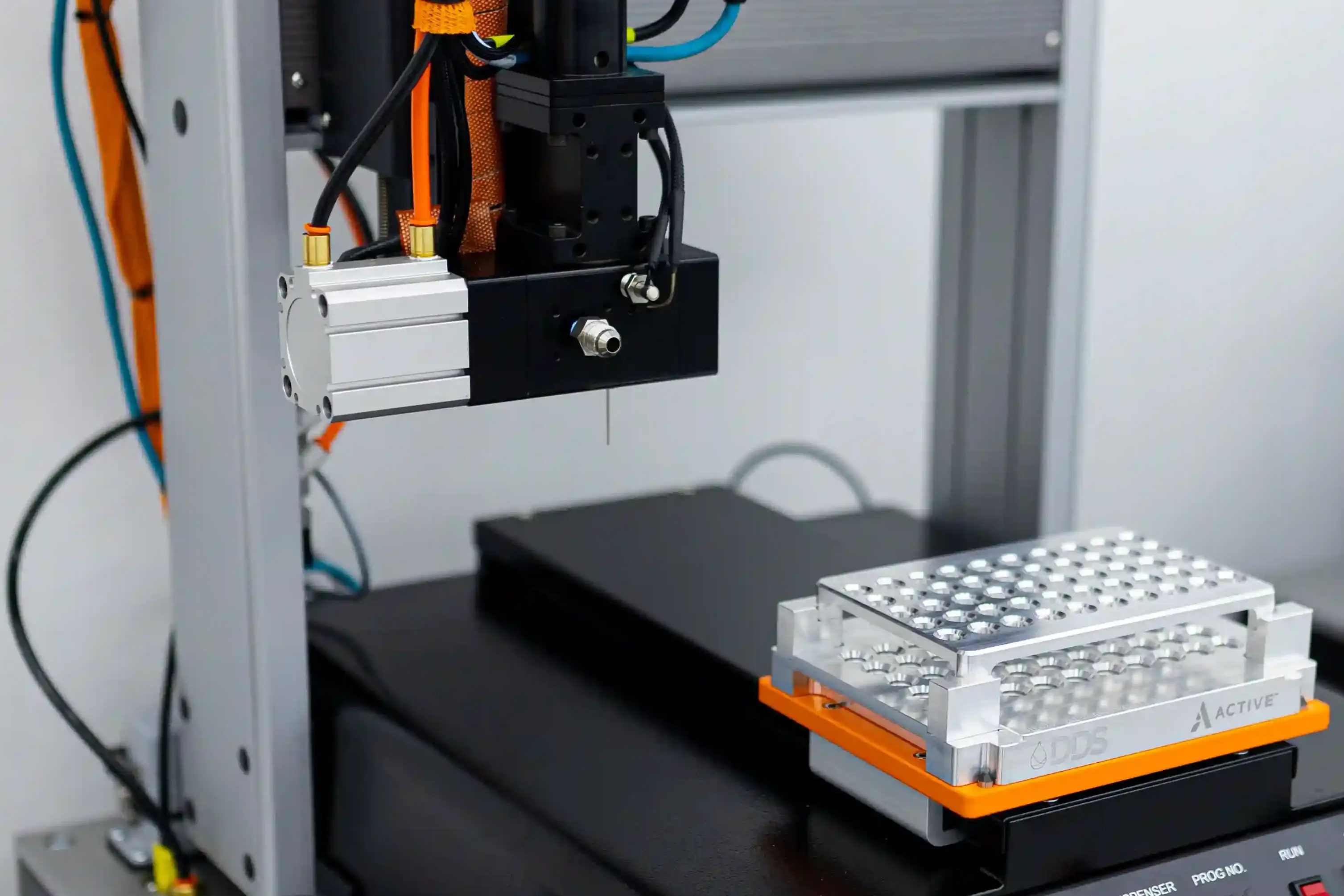

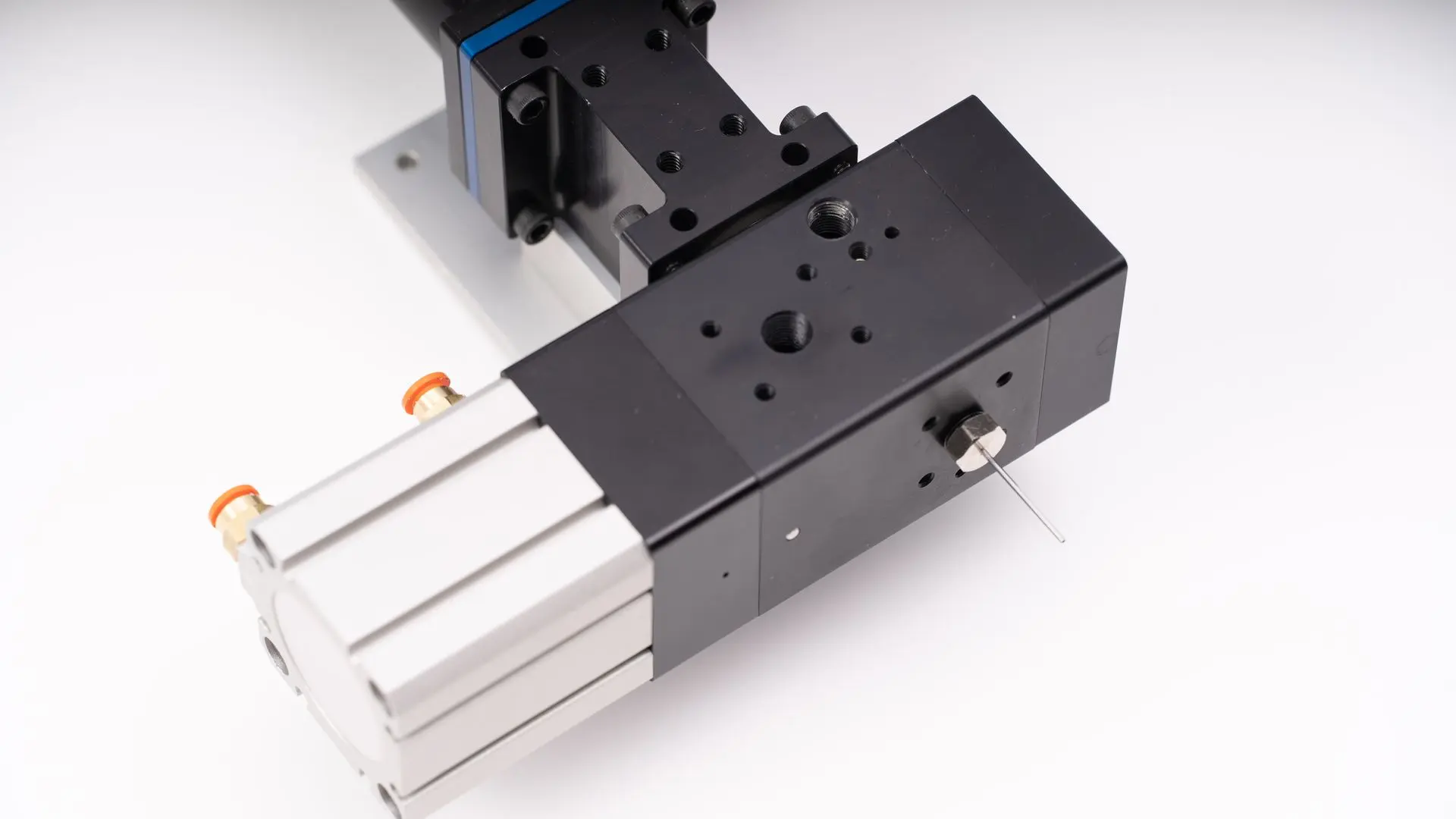

Revolutionary Valve Technology

At the core of the CFS-1800 is our proprietary dispensing valve, engineered exclusively for cannabis applications. Featuring a 316L stainless steel metering rod with servo-driven precision, it delivers ±1% dosing accuracy—even with thick, high-viscosity materials. Unlike check-valve systems that clog and cause inconsistencies, our pneumatic spool valve ensures smooth, repeatable operation at industry-leading low temperatures. The result: reliable fills that preserve potency, flavor, and quality from tank to cartridge.

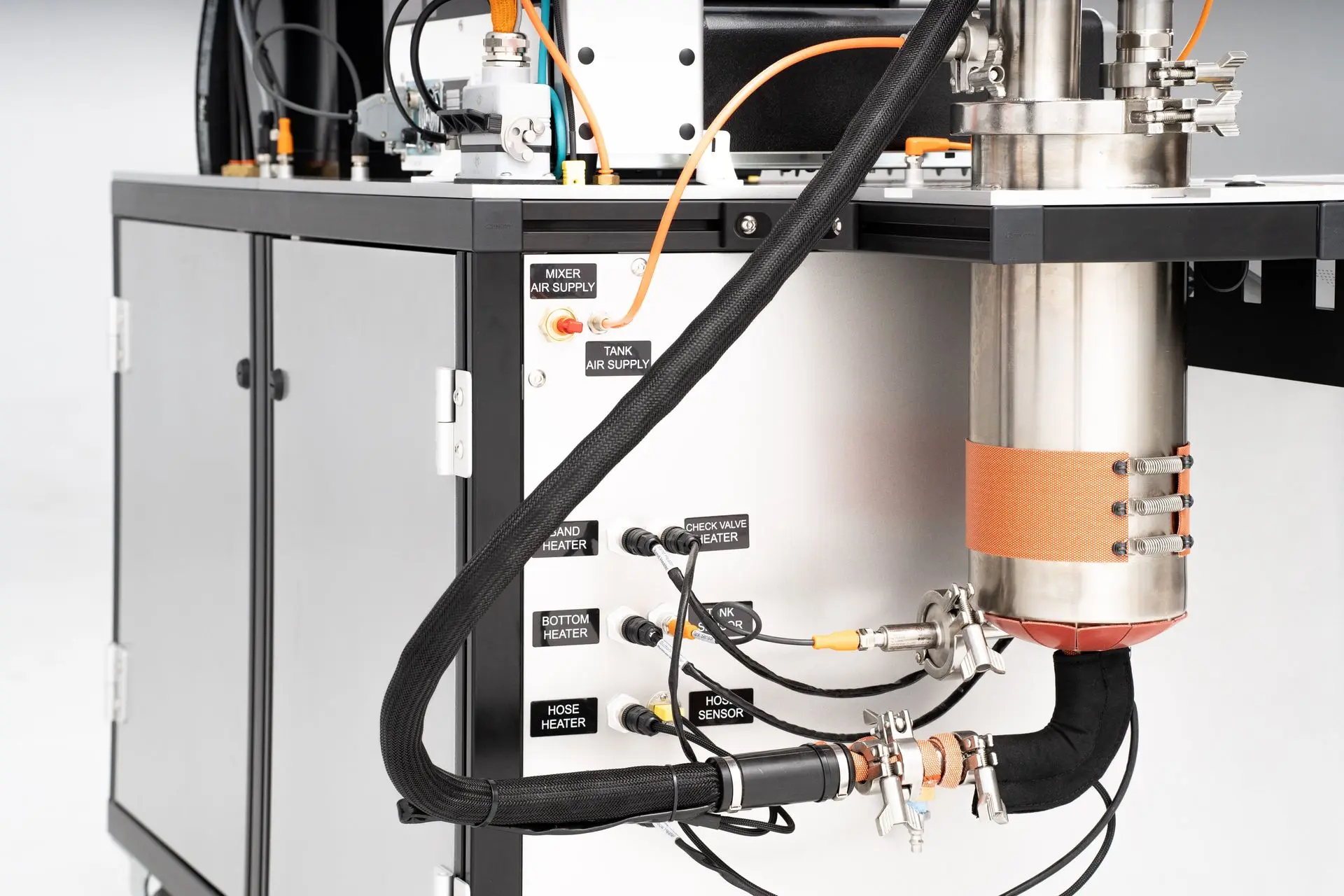

Additional Features of the CFS-1800

The CFS-1800 is designed with industrial-grade construction, modular components for flexible workflows, and integrated 3L or 6L stainless steel reservoir tanks. Every element prioritizes safety, precision, and ease of use—helping your operation run smoothly, reliably, and at peak performance.

6L Reservoir Tank

The 316L Stainless Steel Reservoir Tank is the ideal solution for high-volume distillate production. It features an advanced thermal management system and a non-contact, radar-based level sensor for accurate volume monitoring. An RTD temperature probe measures the actual oil temperature—rather than just the heater temperature—enabling more precise thermal control and consistent dispensing results.

3L Reservoir Tank

The 3L Stainless Steel Reservoir Tank offers all the same advanced features as the 6L model, but is optimized for SKU-intensive operations requiring quick material changeovers. Ideal for smaller rosin, resin, or distillate batches, the 3L tank maximizes operational efficiency with minimal batch loss. Mounted on a linear rail system, the tank lowers for easy filling and raises into position to reduce residual loss by leveraging both gravity and a pressure-assist system.

Industrial-Grade

Built from the ground up with industrial-grade components, the CFS-1800 is designed to run without interruption. Whether you're pushing high volumes or operating around the clock, this machine delivers unmatched reliability and endurance.

Modular by Design

At DDS, we use only top-tier components—but real-world variables are inevitable. Our modular systems make service simple: unplug the old, plug in the new, and get back up and running in minutes.

5-Stage Filtration

Our onboard air filtration system is engineered to protect your product from contamination at every step. With a dedicated 3-stage sanitary-grade filter built in, only sterile, ultra-clean air ever comes into contact with your oil.

High-Speed Pre-Roll Infusion.

Just like the CFM-1800, the CFS-1800 isn’t limited to cartridge filling—it’s also built for high-speed pre-roll infusion. With a simple needle swap and preset infusion programming, operators can infuse up to 1,500 pre-rolls per hour, expanding your product line effortlessly. Designed for versatility and efficiency, the CFS-1800 lets you infuse pre-rolls without disrupting workflow or compromising quality—making it a true multi-format production solution for modern cannabis operations.

Trusted by Industry Leaders

We’re proud to partner with some of the top names in the industry, helping them scale efficiently and consistently.

Discover the CFS-1800 Efficiency

The CFS-1800 delivers repeatable, low-temp cartridge filling with just one operator. Request your free demo today!