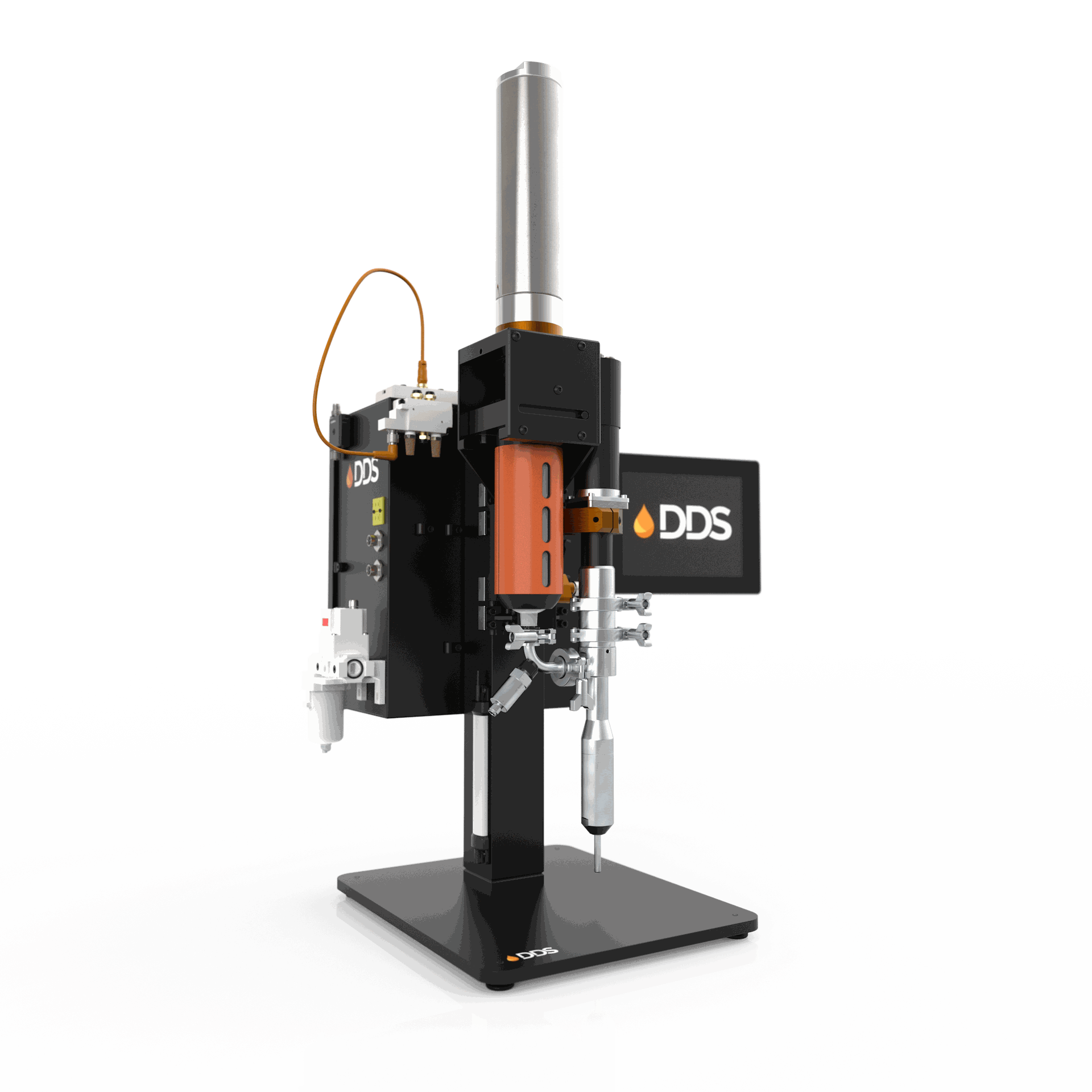

CDS-1000:

Concentrate Dispensing

Fill up to 800 concentrate jars per hour with ±1% dosing accuracy at ambient temperatures.

CDS-1000

Semi-Automated Concentrate Dispensing System

Whether your operation produces a single product with absolute consistency or manages a wide variety of concentrate types, the CDS-1000 adapts without compromise. From badder and butter to sugar and cold-cured rosin, this dispenser is engineered to handle the full spectrum of cannabis concentrate viscosities with precision and reliability.

The CDS-1000 was designed to fully automate concentrate dispensing at a production rate of up to 800 jars per hour. Its precision-engineered dosing mechanism delivers accurate fill weights across all material types—minimizing waste and ensuring uniformity from the first unit to the last.

Backed by a one-year warranty and including professional installation, training, and ongoing technical support, the CDS-1000 ensures seamless operation from day one.

Reliable, High-Quality Fills Every Time

Designed for cannabis concentrates, the CDS-1000 delivers consistent fills at the lowest temperatures in the industry, maintaining flavor and potency.

Fill 800 Jars/Hour

With a production rate of up to 800 concentrate jars per hour, the CDS-1000 sets a new standard for versatility and efficiency. Engineered for precision and consistency, it handles a wide range of concentrate types.

Dispense at 68-72°F

Engineered for precision at ambient temperatures, the CDS-1000 maintains product integrity from start to finish. Achieve accurate fills, preserve delicate concentrate properties, and ensure consistent results with every jar.

±1% Dosing Accuracy

The CDS‑1000 delivers ±1% dosing accuracy thanks to its smooth-flow pump and precision plunger feed system. Even the most viscous concentrates are filled consistently, preserving flavor, potency, and batch homogeneity.

Eastside Alchemy Powers Up Rosin Production with the CDS-1000

The CDS-1000 has transformed Eastside Alchemy’s rosin production. By dispensing rosin at or below room temperature, it preserves terpenes and material integrity while handling a wide range of concentrates—from badder and butter to live and cured rosin—with unmatched precision.

Equipped with a low-shear pharmaceutical-grade pump, the CDS-1000 streamlines workflow, reduces manual handling, and minimizes waste. The result: faster, more consistent fills, improved throughput, and elevated product quality—taking production processes to the next level.

Advantages of the CDS-1000

Every component of the CDS-1000 is built from the ground up for cannabis, including its pharmaceutical-grade pump and efficient material feed system—ensuring unmatched accuracy and consistency every concentrate jar filled.

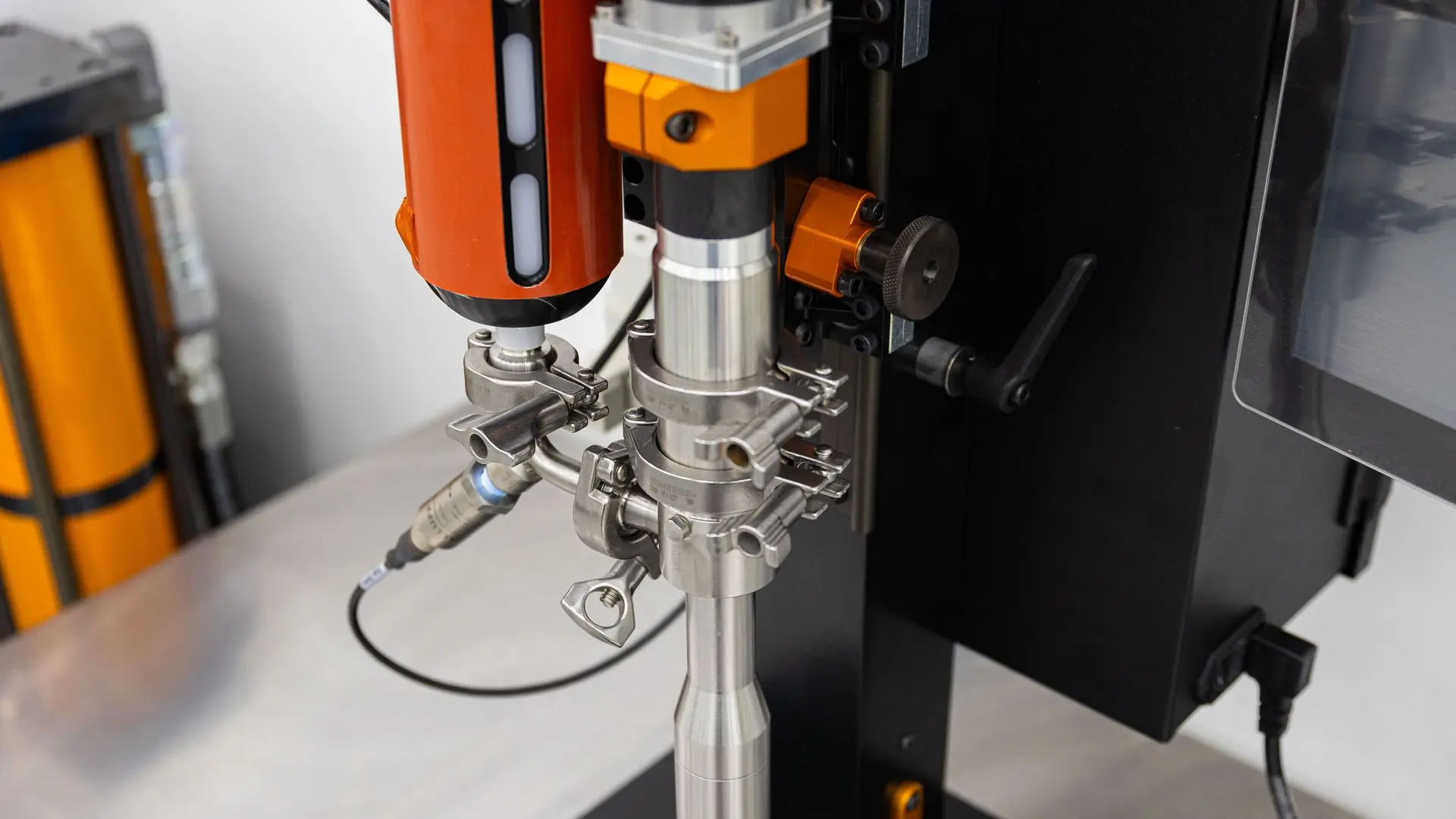

Pharmaceutical-Grade Pump

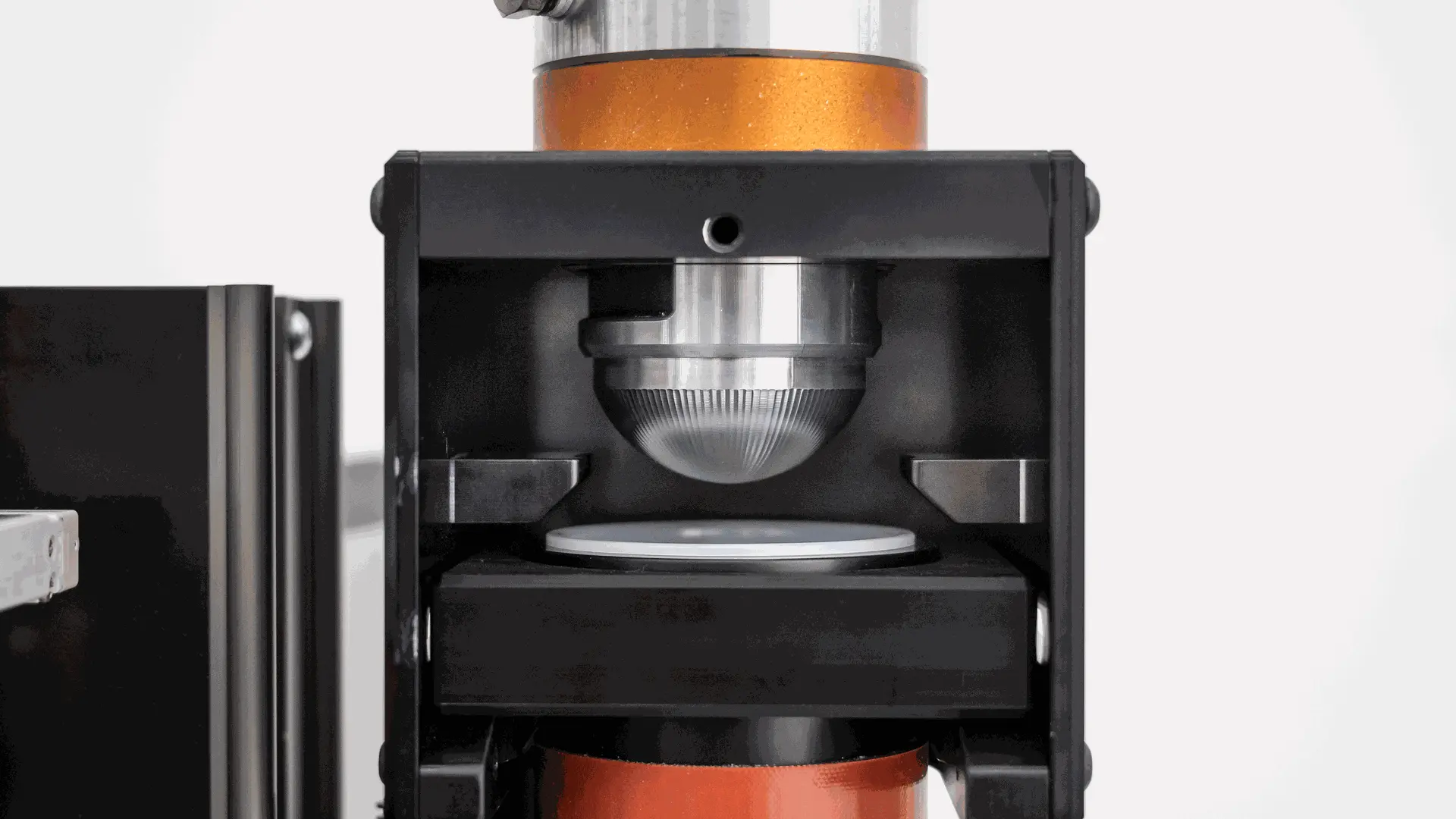

At the heart of the CDS-1000 is a pharmaceutical-grade progressive cavity dosing pump, engineered for precision, durability, and versatility. Its low-shear rotor and stator design ensures smooth, consistent dosing—even with high-viscosity or particulate-rich concentrates.

Unlike traditional pumps, it minimizes pulsation and turbulence, preserving terpenes and preventing degradation from excess heat or shear. Built from chemically resistant FFKM and 316L stainless steel, it’s fully GMP- and FDA-compliant, offering long-term reliability and easy cleanability. From live rosin and resin to badder, budder, and sauce, this pump delivers accurate, repeatable performance—batch after batch.

Efficient Material Feed System

Unlike traditional pressure pot feed systems that rely on compressed air, the CDS-1000 uses a precision tube-and-plunger feed mechanism for consistent, controlled material flow. This design is essential for maintaining dosing accuracy and ensuring stable performance across any concentrate type.

Pressure pots can cause terpene loss and material inconsistency, especially with thick or semi-solid concentrates. The CDS-1000’s plunger system maintains even pressure throughout the batch, preserving product homogeneity and quality from start to finish.

To optimize control, a closed-loop pressure feedback circuit continuously monitors and adjusts feed force in real time—delivering exceptional dosing precision, repeatability, and reduced operator oversight, even with the most challenging materials.

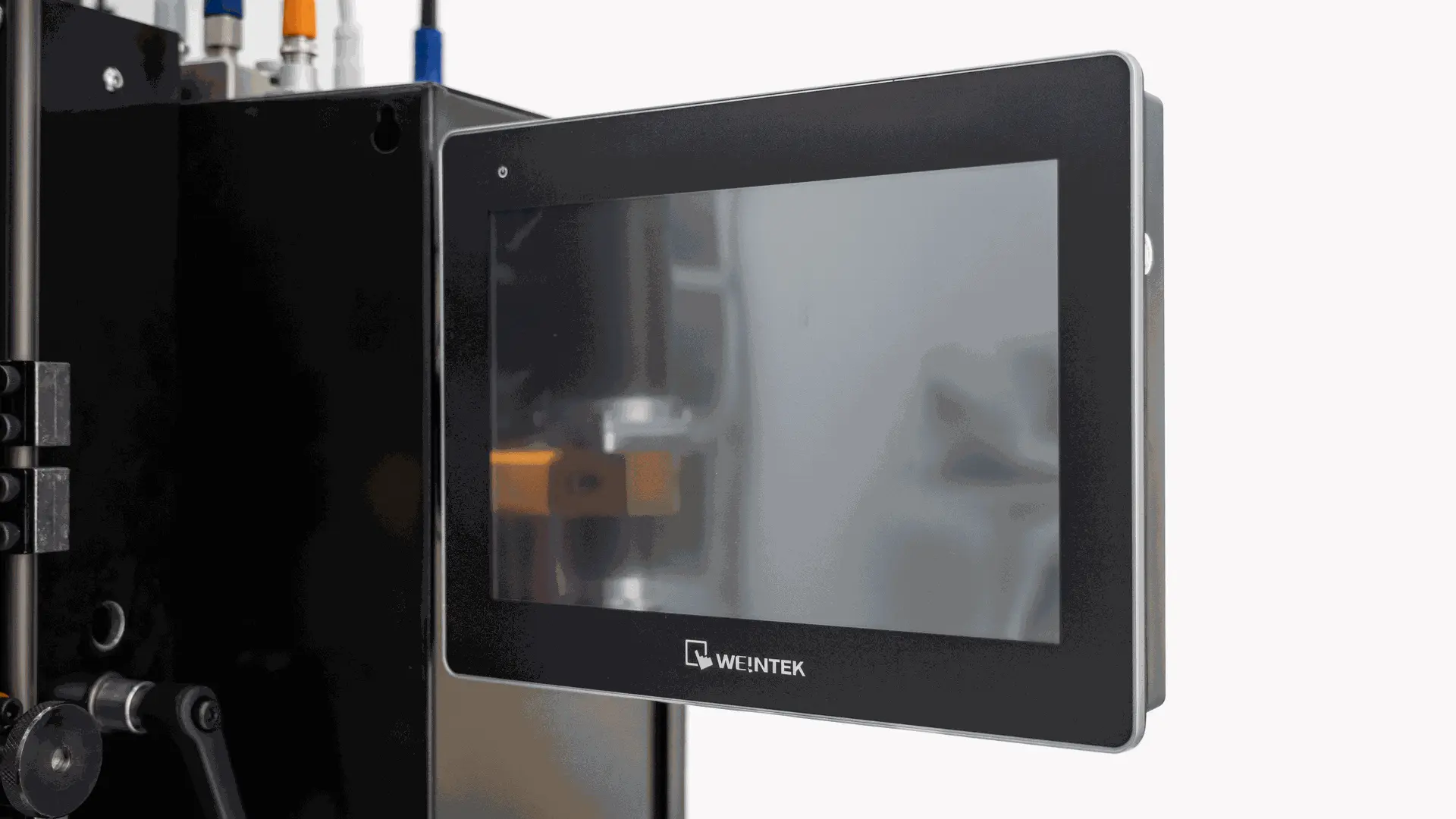

Accurate Batch Calibration

The challenge of dispensing concentrates goes beyond pump selection and feed control—material density variability presents another key obstacle. While positive displacement pumps measure doses volumetrically, the cannabis industry is driven by package weight, not volume.

The CDS-1000 concentrate dispenser machine solves this with a simple batch calibration step. Operators dispense 1 mL of product, weigh it, and enter the weight into the touchscreen HMI. The system then calculates the actual material density and automatically adjusts the dispense volume to match a 1-gram target. This ensures accurate, weight-based dosing—making it a smart option for producers seeking the best concentrate dispensing machine to maximize yield without over- or under-dispensing.

Additional Features of the CDS-1000

The CDS-1000 is designed with industrial-grade construction and modular components for flexible workflows. Every element prioritizes safety, precision, and ease of use—helping your operation run smoothly, reliably, and at peak performance.

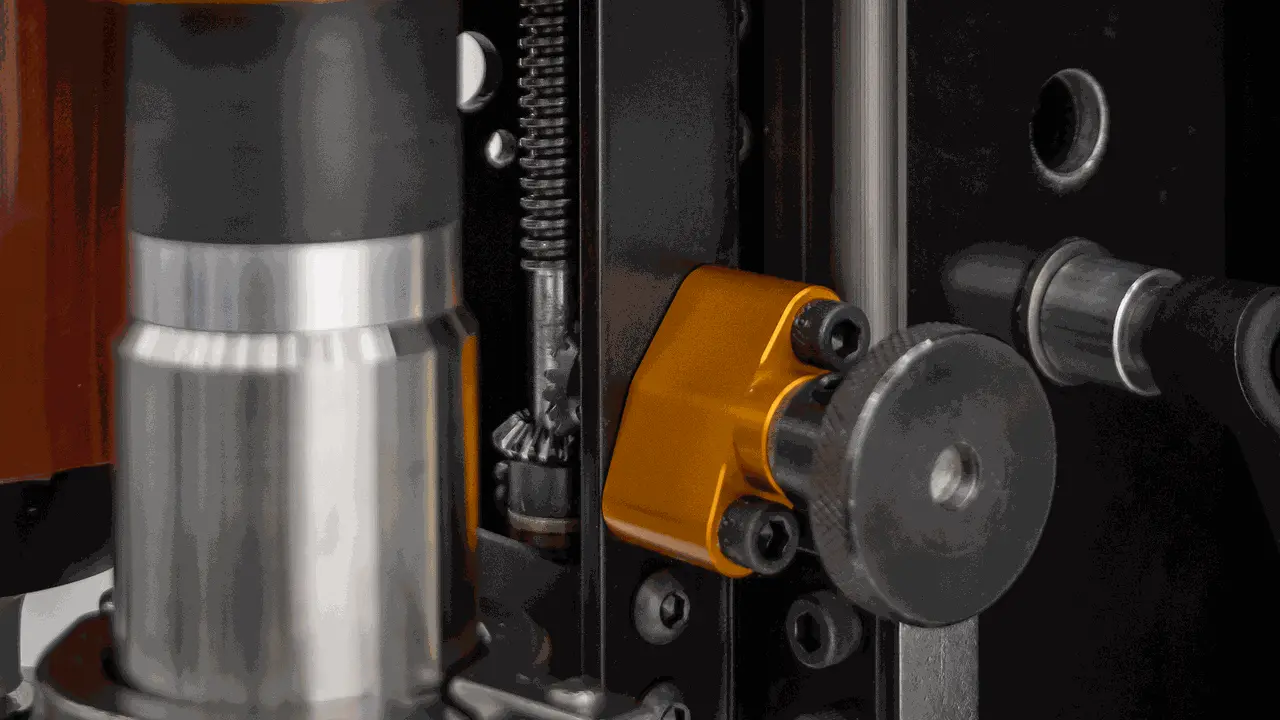

Operator Ergonomics

The CDS-1000 is built for comfort, safety, and efficiency. Its linear rail system lets operators adjust pump height in seconds—no tools required—while the integrated counterweight ensures smooth, controlled motion and prevents accidental slamming. This ergonomic, user-focused design reduces fatigue, speeds changeovers, and protects equipment, making the CDS-1000 a reliable choice for high-performance concentrate dispensing.

Industrial-Grade

Built from the ground up with industrial-grade components, the CDS-1000 is designed to run without interruption. Whether you're pushing high volumes or operating around the clock, this machine delivers unmatched reliability and endurance.

Modular by Design

At DDS, we use only top-tier components—but real-world variables are inevitable. Our modular systems make service simple: unplug the old, plug in the new, and get back up and running in minutes.

Touchscreen Controls

Intuitive interface simplifies batch setup, calibration, and real-time adjustments—empowering operators with consistent and reliable performance.

Tool-Free Cleaning and Fast Changeover

Engineered for rapid material change between batches or SKUs, minimizing downtime and boosting production flexibility.

Trusted by Industry Leaders

We’re proud to partner with some of the top names in the industry, helping them scale efficiently and consistently.

Maximize Concentrate Output with the CDS-1000

Take your concentrate workflow to the next level. Request a free demo!