Labor Cost Analysis: How Automation Reduces Cannabis Production Overhead

As cannabis markets mature and wholesale prices compress, production efficiency separates profitable operations from struggling ones. The median cost to grow cannabis flower indoors was $472 per pound in 2020, with labor representing one of the largest controllable expenses. For vape cartridge and concentrate manufacturers, labor economics are even more critical—and automation offers a proven path to sustainable margins.

The Hidden Cost of Manual Production

Labor costs in cannabis cultivation have climbed significantly, with hourly rates for workers ranging from $14-$25/hour. But direct wages tell only part of the story. Manual cartridge filling operations face compounding expenses that erode profitability:

Production Bottlenecks: A skilled operator manually fills 200-300 cartridges per hour. To match the output of a single automated system producing 14,400 cartridges per shift requires 6-9 full-time employees working simultaneously.

Quality Control Burden: Manual processes demand additional staff for inspection, rework, and waste management. When fill accuracy varies by +/- 3-5%, dedicated QC personnel become essential overhead.

Training and Turnover: While cannabis employment dipped 3.4% in 2024, the industry still supports 425,002 full-time equivalent jobs, reflecting ongoing workforce mobility that creates constant training costs.

Physical Strain: Repetitive manual tasks lead to fatigue, reduced accuracy over shifts, and potential workers' compensation claims that don't appear on standard labor reports.

Automation ROI: The Numbers That Matter

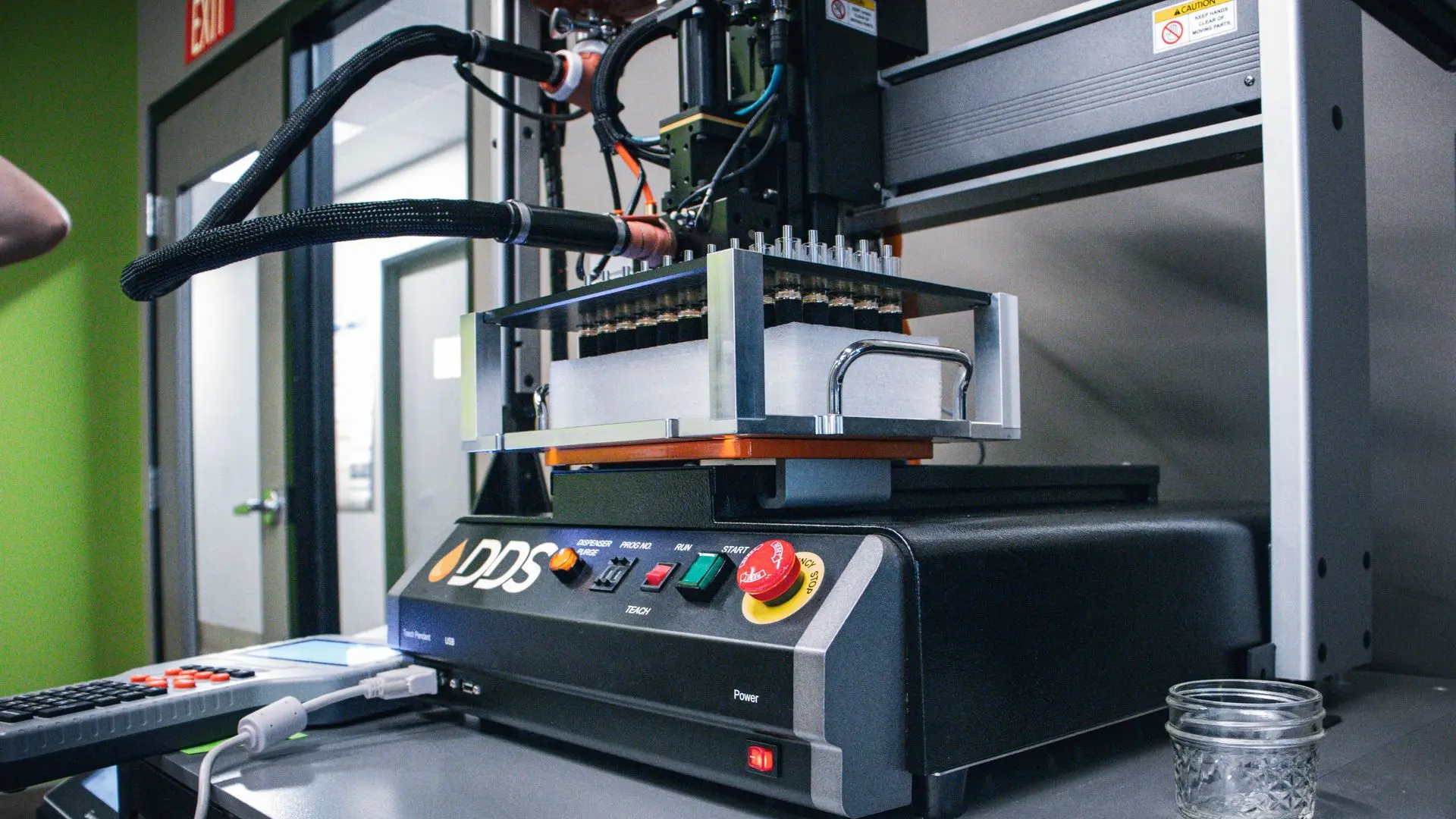

The case for automation becomes clear when examining production capacity and consistency. Detroit Dispensing Solutions' CFM-1800 and CFS-1800 automated filling systems deliver 1,800 cartridges per hour with just one operator—equivalent output to 6-9 manual workers.

Real Labor Savings Calculation

Manual Operation (14,400 carts/shift):

- 8 operators @ $18/hour × 8 hours = $1,152

- 1 supervisor @ $25/hour × 8 hours = $200

- 1 QC inspector @ $20/hour × 8 hours = $160

- Daily total: $1,512 | Annual: $393,120

Automated Operation (14,400+ carts/shift):

- 1 operator @ $22/hour × 8 hours = $176

- Minimal supervision = $50

- Daily total: $226 | Annual: $58,760

Annual labor savings: $334,360 (85% reduction)

Proper facility design and automation technology can reduce labor costs to produce a pound of cannabis by 62.9%, making the investment case even stronger for comprehensive automation strategies.

Waste Reduction Multiplies Savings

Labor costs represent just one savings category. Automated dispensing systems dramatically reduce product waste through precision filling. If distillate costs $10/gram and manual processes waste 2% while automation wastes 0.3%:

- Manual waste: 288 grams × $10 = $2,880/shift

- Automated waste: 43 grams × $10 = $430/shift

- Daily savings: $2,450 | Annual: $637,000

The CFM-1800 and CFS-1800 achieve +/- 1% fill accuracy using precision dispensing technology designed specifically for high-viscosity cannabis oils, compared to +/- 3-5% variability common with manual methods.

The Payback Period

Equipment investment typically ranges from $75,000-$150,000 for quality automated filling systems. Using conservative figures:

Investment: $100,000

Combined annual savings: $971,360 (labor + waste)

Payback period: 1.2 months

Even accounting for installation and training costs adding $3,500, most operations achieve full payback within 2-3 months. After that, nearly $1 million annually flows directly to the bottom line.

Beyond Direct Savings: Strategic Advantages

The U.S. cannabis market is projected to reach $32.1 billion in 2024 and $58 billion by 2030. As markets expand and competition intensifies, automation delivers advantages beyond immediate cost reduction:

Consistent Quality: Low-temperature filling technology preserves terpene profiles while +/- 1% accuracy ensures every customer receives the exact product they paid for, building brand loyalty and reducing complaints.

Scalability Without Complexity: Manual operations scale linearly…double output requires double staff. Automated systems scale efficiently. Add a second CFM-1800 and double output with just one additional operator, not sixteen.

Workforce Redeployment: Automation is revolutionizing the cannabis industry, with facilities in the 5,000-10,000 square foot range hitting an inflection point where automation becomes cost-effective. When machines handle repetitive tasks, employees can focus on quality control, process optimization, compliance documentation, and product development, higher-value roles that improve both job satisfaction and operational capability.

Competitive Positioning: The cannabis industry posted $30.1 billion in legal retail sales in 2024, a 4.5% increase year-over-year, but price compression continues in mature markets. Companies maintaining healthy margins are those delivering consistent quality at competitive prices - a combination requiring operational excellence that automation enables.

Making the Transition

Not every operation needs to invest in maximum-capacity systems immediately. Detroit Dispensing Solutions offers options designed for different production scales:

- CFS-1800: Compact footprint without integrated press, ideal for operations adding automation or space-constrained facilities

- CFM-1800: Full-featured system with 30,000 lbs capping force for high-volume production

Both systems deliver identical filling technology with low-temperature capabilities that preserve product integrity. Systems designed and manufactured in the USA provide faster support response times and easier access to technical expertise than imported alternatives.

The Bottom Line

Cannabis production costs range from $150 to $1,000 per pound depending on location and efficiency. In an industry facing regulatory complexity and increasing consumer expectations, labor efficiency separates profitable operations from struggling ones.

The manufacturers winning market share aren't necessarily those with the lowest prices, they're delivering consistent quality at competitive prices while maintaining healthy margins. That combination requires operational excellence, and operational excellence at scale requires automation.

For cannabis processors producing vape cartridges and concentrates, the labor cost analysis is clear: automation delivers measurable ROI within months while improving product quality and positioning operations for sustainable growth.

Ready to reduce labor costs and scale your cannabis production? Learn how Detroit Dispensing Solutions' automated cartridge filling systems can transform your operation. Contact us for a detailed ROI analysis specific to your production volume.

Sources:

- Trym Cannabis Statistics

- Statista Production Costs Analysis

- MJBiz Daily Economic Impact Report

- Cannabis Equipment News Industry Report

- Next Big Crop Production Analysis