Cartridge Filling

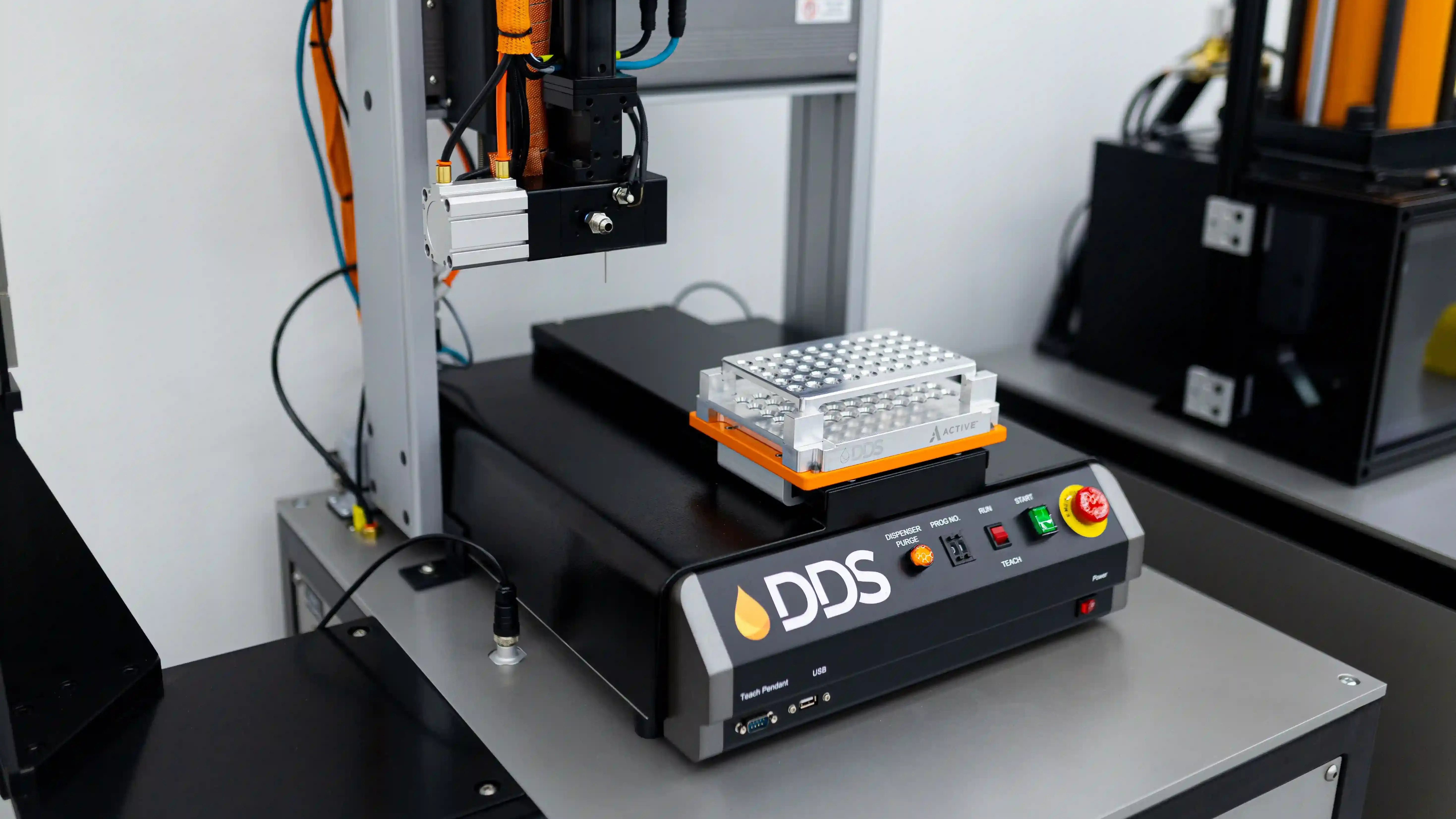

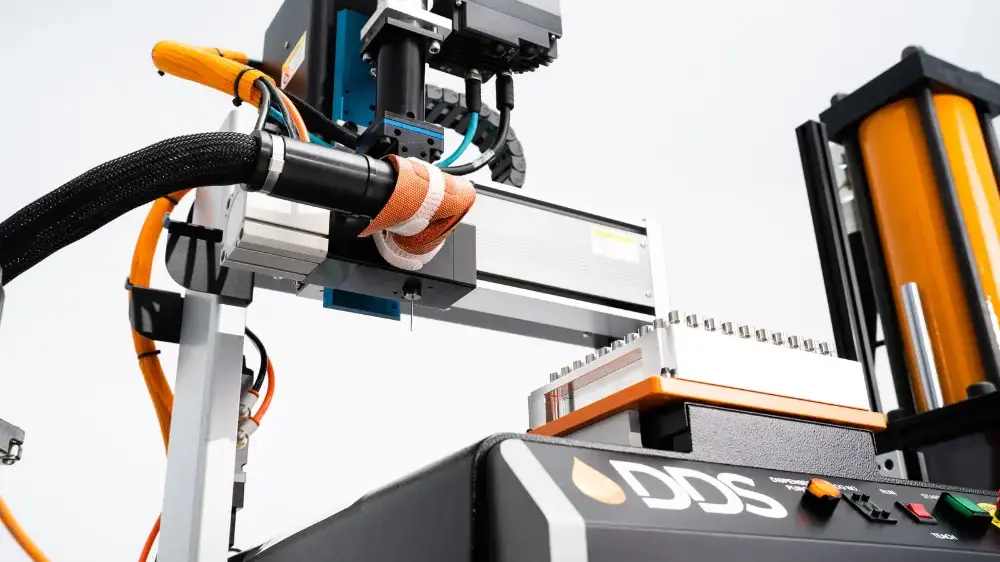

Equipment

DDS cartridge fillers streamline production while maintaining unmatched quality and consistency. Our cartridge fillers integrate seamlessly with the FX-8 automated solution for complete workflow automation.

Efficiency and Precision You Can Rely On

Our CFM-1800 and CFS-1800 systems are engineered to streamline cartridge filling with unmatched accuracy and consistency. Designed to maximize throughput and reduce downtime, these machines support both growing operations and large-scale manufacturers, delivering repeatable, high-quality results while maintaining compliance and boosting overall productivity.

Our systems are trusted by processors seeking the best cartridge filling machine for high-volume production. From semi-automatic filler setups for growing businesses to fully automated solutions for large-scale manufacturing, we offer equipment designed to match your throughput and compliance needs, along with supporting accessories and ancillary equipment.

CFM-1800: Automated Cartridge Filling & Capping

The CFM‑1800 is built for high-throughput cartridge filling and capping in cannabis production — up to 1,800 cartridges per hour with ±1% fill accuracy. It features the industry’s lowest dispensing temperature for handling live resins and distillates, along with a powerful built-in press for reliable capping.

CFS-1800: Automated Cartridge Filling

The CFS‑1800 is a compact, high-throughput cartridge-filling system capable of up to 1,800 cartridges per hour with ±1% fill accuracy. Designed for live resins and distillates, it features the industry’s lowest dispensing temperature and a true-rod positive-displacement valve.

Why Choose Detroit Dispensing Solutions?

With the industry’s lowest dispensing temperature, ±1% accuracy, and one of the highest throughputs available, our equipment delivers speed, precision, and repeatability—helping your lab maximize efficiency with minimal labor.

Increased Production Efficiency

Automation dramatically boosts production capacity compared to manual vs automated cartridge filling methods. Our automated dispensing systems enable businesses to meet high demand without sacrificing accuracy or product quality—reducing labor costs while maximizing efficiency and throughput.

Consistent & Accurate Dosing

Consistency is essential in the industry, where precise concentrations are critical for compliance, safety, and consumer confidence. DDS systems deliver exact, repeatable doses with every fill—helping producers maintain regulatory standards, ensure product quality, and build lasting trust with their customers.

Industry's Lowest Dispensing Temperature

DDS systems deliver the lowest dispensing temperatures in the industry, preserving potency, flavor, and consistency across every cartridge, pre-roll, or concentrate jar. High-throughput, precise, and reliable, our automated solutions keep your lab efficient while safeguarding product quality.

Trusted by Industry Leaders

We’re proud to partner with some of the top names in the industry, helping them scale efficiently and consistently.

Frequently asked questions

The CFM-1800 includes an integrated 30,000-lb capping press for automated filling and capping, while the CFS-1800 is a compact system focused on filling only. Both systems fill 1,800 cartridges or infuse 1,500 pre-rolls per hour with ±1% accuracy and feature the same low-temperature filling technology.

Low-temperature filling means dispensing cannabis oil at the lowest possible temperatures (as low as 50°C) to preserve terpenes and prevent degradation. DDS systems operate at industry-leading low temperatures compared to competitors that require 70-80°C.

Both the CFM-1800 and CFS-1800 deliver ±1% dosing accuracy using true-rod positive displacement valve technology, ensuring consistent fill weights across every cartridge.

The CFM-1800 and CFS-1800 both fill up to 1,800 cartridges per hour with a single operator, producing 14,000+ cartridges per 8-hour shift.

DDS cartridge filling systems handle distillate, live resin, and other high-viscosity cannabis oils. The low-temperature filling capability is particularly beneficial for preserving terpenes in live resin products.

No. Both the CFM-1800 and CFS-1800 require only one operator to achieve full production capacity of 1,800 cartridges per hour.

Automated systems can reduce labor costs by 85% or more compared to manual filling. A single operator on an automated system can produce the same output as 6-9 manual fillers, generating annual labor savings of $300,000+ for mid-sized operations.

Yes. Low-temperature filling combined with rapid capping prevents oil from soaking into cartridge atomizers, which is a primary cause of clogging and leaking. The ±1% fill accuracy also prevents overfilling that leads to leaks.

DDS cartridge filling systems offer the option of a 3L or 6L 316L stainless steel reservoir, allowing operators to select the capacity that best fits their production needs and throughput requirements.

Yes. All DDS equipment is designed, engineered, and manufactured in Troy, Michigan, USA, providing faster support response times and easier access to service compared to imported equipment.

Find the Right Cartridge Filler for Your Lab

From vape cartridges to pre-roll infusion, DDS provides high-efficiency production solutions. Fill out the form to get personalized guidance for your workflow and goals.