Why Data Should Guide Cannabis Automation Investments

In the rapidly evolving world of cannabis concentrate packaging, cartridge filling machine automation technology has become a crucial differentiator for operators looking to scale. The promise of faster throughput, minimal waste, and reduced operator error is enticing—but only if those claims hold up in the real world when selecting the best cartridge filling machine.

There is a growing divide between automated filling systems that promise high-volume output on paper and vape cartridge filling machines that consistently deliver it on the production floor. That's why it's crucial to distinguish between equipment that markets well and THC oil cartridge filler equipment that performs consistently.

Best Cartridge Filling Machine Claims vs. Reality

There are multiple well-known cartridge dispensing solutions on the market known for bold claims, advertised fill rates that, at first glance, seem almost too good to be true. These rates often exclude key parameters like material temperature, setup time, hardware or material changeovers.

For example, most dispensing equipment manufacturers fail to disclose the oil temperature required to hit their advertised throughput. In reality, many systems rely on overheating the oil to reduce viscosity and increase speed, a tradeoff that can degrade terpene profiles, affect potency, and ultimately compromise product quality and brand integrity. After all, what's the point of filling faster if it comes at the cost of your product?

In real-life operations, users report significant slowdowns due to frequent recalibrations, inconsistent fill levels, and operator intervention that negates the value of “automation." What's marketed as "autonomous" quickly turns into “operator-dependent,” adding labor, downtime, and frustration to what should be a streamlined semi-automatic vape filler process.

A Different Approach: Data Driven, Operator-Focused

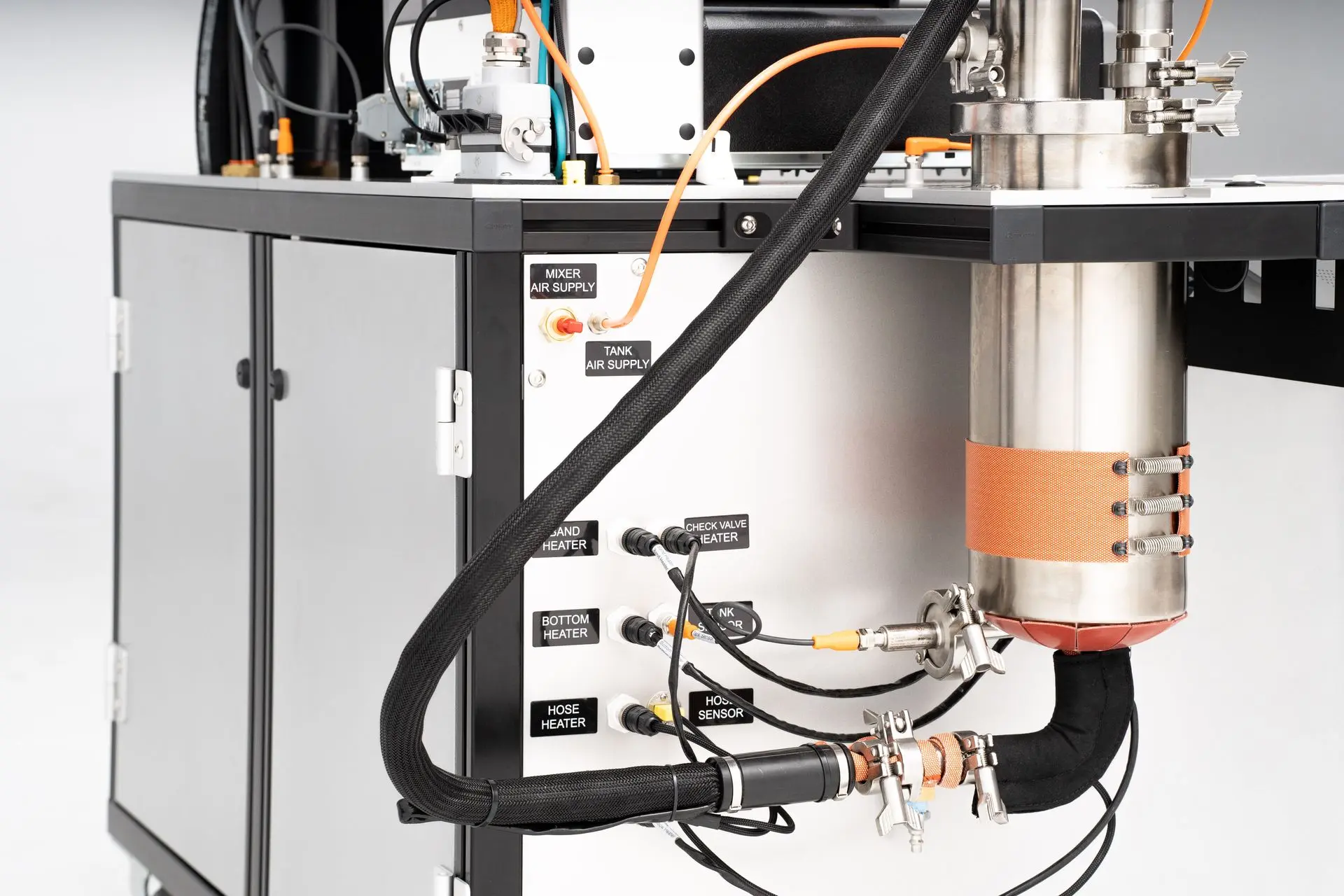

Detroit Dispensing Solutions (DDS) takes a fundamentally different approach to vape cartridge filling machine automation, one rooted in transparency, real-world performance, and product integrity.

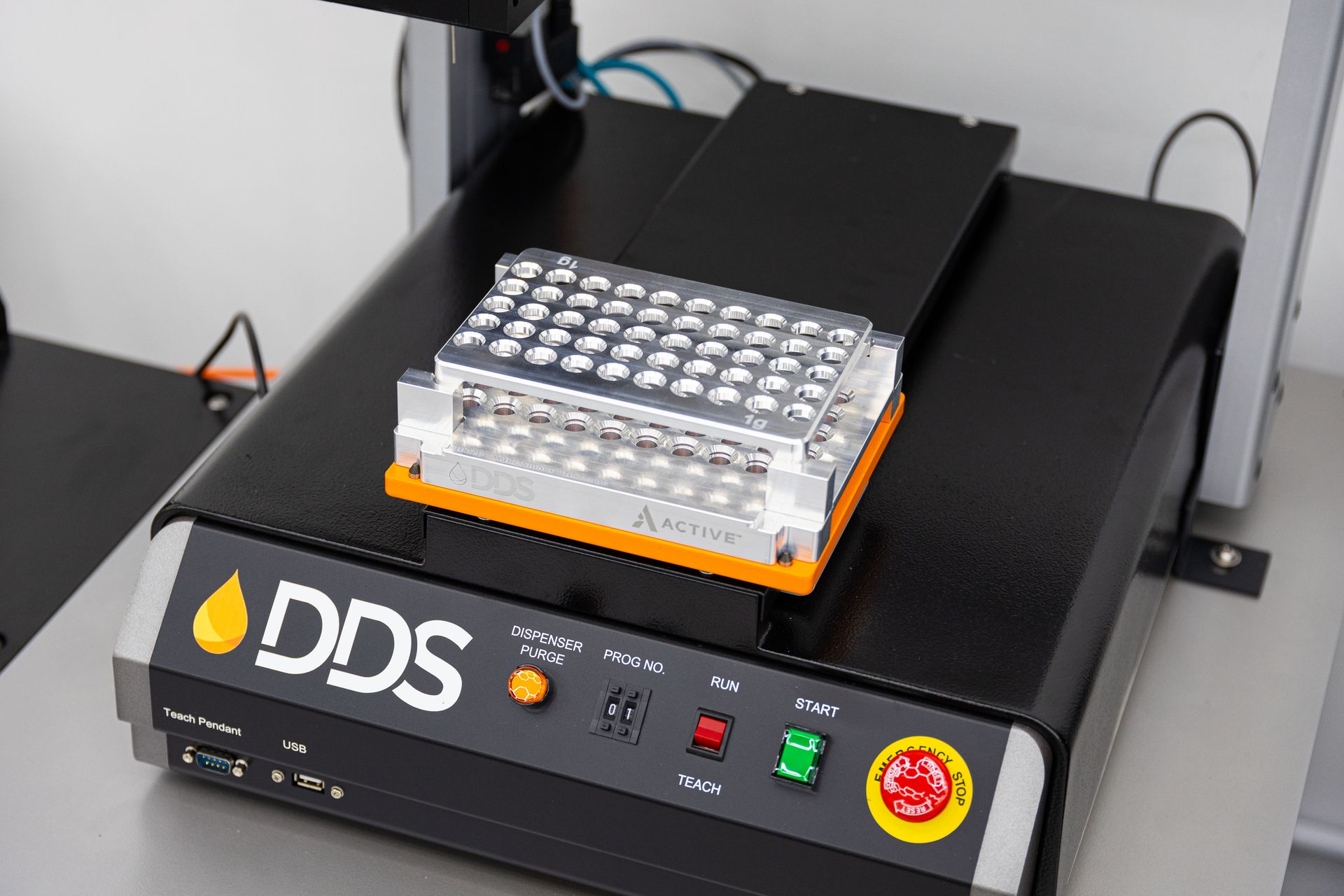

All DDS throughput data is based on standard 8- or 10-hour manned shifts during full production cycles, with both filling and capping accounted for. The systems' streamlined workflow, supported by custom jigs, enables operators to move efficiently from fill to cap with minimal handling and no need to re-stage cartridges—something most cartridge filling machine competitors fail to include in their performance claims.

DDS jigs also allow operators to cap directly in the original foam trays supplied by cartridge manufacturers. Without a jig, this process is generally impossible, forcing mouthpieces to be placed by hand, slowing output and increasing ergonomic strain and inconsistency.

For operators focused on preserving terpenes and product integrity during filling, DDS equipment is engineered with precise temperature control mechanisms that maintain oil at optimal filling temperatures—avoiding overheating while ensuring smooth, consistent flow. This helps producers retain flavor, potency, and brand quality in every cartridge.

Why Jigs Outperform Vision Systems

One of the most overlooked differences in cartridge automation is how products are aligned for filling and capping. While some brands promote camera-based “vision systems” as cutting-edge automation, they often introduce more problems than they solve.

DDS uses precision jig systems—and for good reason:

- Faster, frictionless setup: Jigs don’t need calibration or lighting adjustments.

- Greater reliability: Jigs hold cartridges in fixed positions with no room for alignment drift.

- Original packaging compatible: Fill and cap directly in supplier foam trays—no repackaging needed.

- Simpler for operators: No vision software, fewer errors, and lower training burden.

- True automation: Jig-based setups allow repeatable, high-speed operation across SKUs with minimal operator intervention.

In contrast, vision systems tend to slow down the filling process as the system needs to register each individual device rather than relying on a coordinate based system for alignment.

Choosing the Best Cartridge Filling Machine: Trust What You Can Measure

In an industry where compliance, consistency, and consumer experience are everything, you can't afford to gamble on hype. Operators shouldn't have to "work around" their THC oil cartridge filler automation equipment or rely on unverifiable marketing claims.

If your production floor is your profit center, then your automated filling equipment should be proven, data-backed, and purpose-built. When evaluating the best vape cartridge filling machine for your operation, consider:

- Real-world throughput data from actual production environments

- Operator training requirements and ease of use

- Maintenance and calibration needs

- Integration with existing workflows

Ready to learn more about DDS' vape filler options? Contact our team for in-depth performance data and system specs.