DDS Benchtop

Cartridge Filling System

Fill vape cartridges and devices with ±1% dosing accuracy at industry-leading low temperatures.

DDS Benchtop

Cartridge Filling System

By popular demand, we’ve brought the trusted CFM-1800 technology to a Benchtop Cartridge Filler. Featuring a true-rod positive displacement valve engineered for cartridge filling and a custom thermal system, it delivers precise, metered dispensing of distillate and live resin at industry-leading low temperatures—capable of filling 1,200–1,400 devices per hour, depending on the operator.

The Benchtop Filler is backed by a one-year warranty and includes professional installation, training, and ongoing technical support to ensure seamless operation from day one.

Compact, Precision Cartridge Filling

Compact yet powerful, our Benchtop Cartridge Filler combines precision, speed, and ease of use—delivering consistent results every time.

Fill Up to 1,200 - 1,400 Devices Per Hour

High-speed, semi-automated filling designed for consistent, metered cartridges at industry-leading low temperatures.

*Actual output varies by operator.

Dispense Distillate at 50°C

Operating at industry-leading low temperatures, our Benchtop Cartridge Filling machine protects your product from heat degradation. Every fill maintains consistent potency, rich flavor, and the full profile of delicate terpenes.

±1% Dosing Accuracy

Designed for cannabis, the DDS Benchtop Filler uses servo-driven precision and a pneumatic spool valve to deliver ±1% dosing accuracy, ensuring smooth, repeatable fills for every formulation.

Advantages of the DDS Benchtop Filler

Every component of the DDS Benchtop Filler is built from the ground up for cannabis, including its proprietary valve technology and 1.5L reservoir tank—ensuring unmatched accuracy and consistency every cartridge filled.

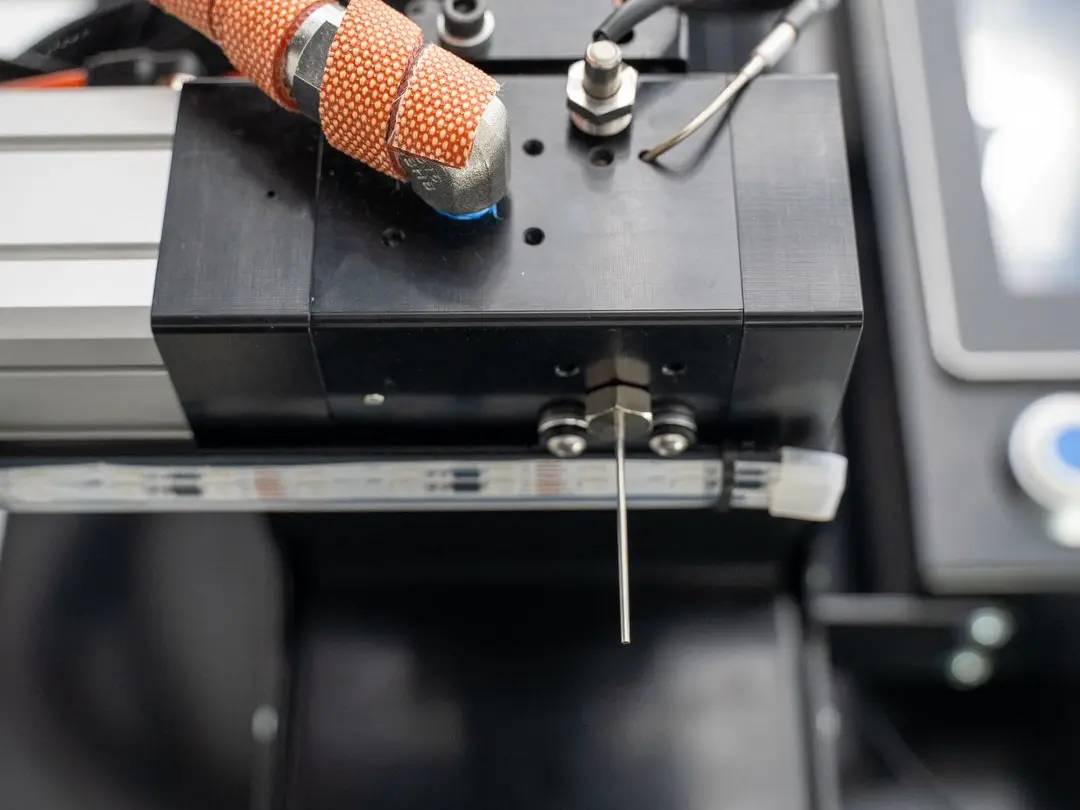

Revolutionary Valve Technology

At the core of the Benchtop Filler is our proprietary dispensing valve, engineered exclusively for cannabis applications. Featuring a 316L stainless steel metering rod with servo-driven precision, it delivers ±1% dosing accuracy—even with thick, high-viscosity materials. Unlike check-valve systems that clog and cause inconsistencies, our pneumatic spool valve ensures smooth, repeatable operation at industry-leading low temperatures. The result: reliable fills that preserve potency, flavor, and quality from tank to cartridge.

1.5L Reservoir Tank

Ideal for rosin, resin, or distillate batches, the system’s 1.5L 316 stainless steel reservoir maximizes efficiency with minimal batch loss and features an ultra-short fluid path to further reduce residual material. Its high-capacity design cuts refill frequency and downtime, enabling faster cycles, fewer interruptions, and a smoother, more consistent cartridge-filling workflow.

Additional Features of the DDS Benchtop Filler

Engineered with industrial-strength components and a small footprint, the DDS Benchtop Filler brings precision, safety, and simplicity to cartridge production—helping your team operate efficiently and confidently.

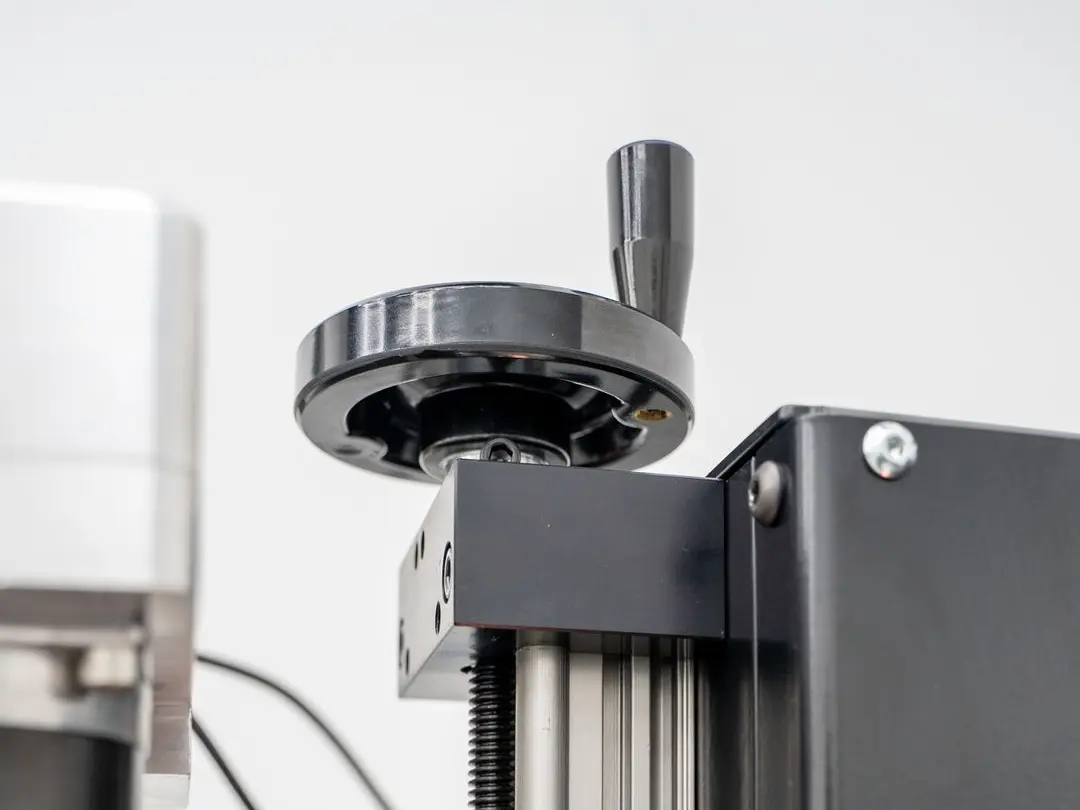

Operator Ergonomics

Designed for comfort, safety, and all-day performance, the DDS Benchtop Filler allows effortless, tool-free vertical height adjustments. The ergonomic design reduces fatigue and keeps operators moving efficiently through high-volume cartridge filling.

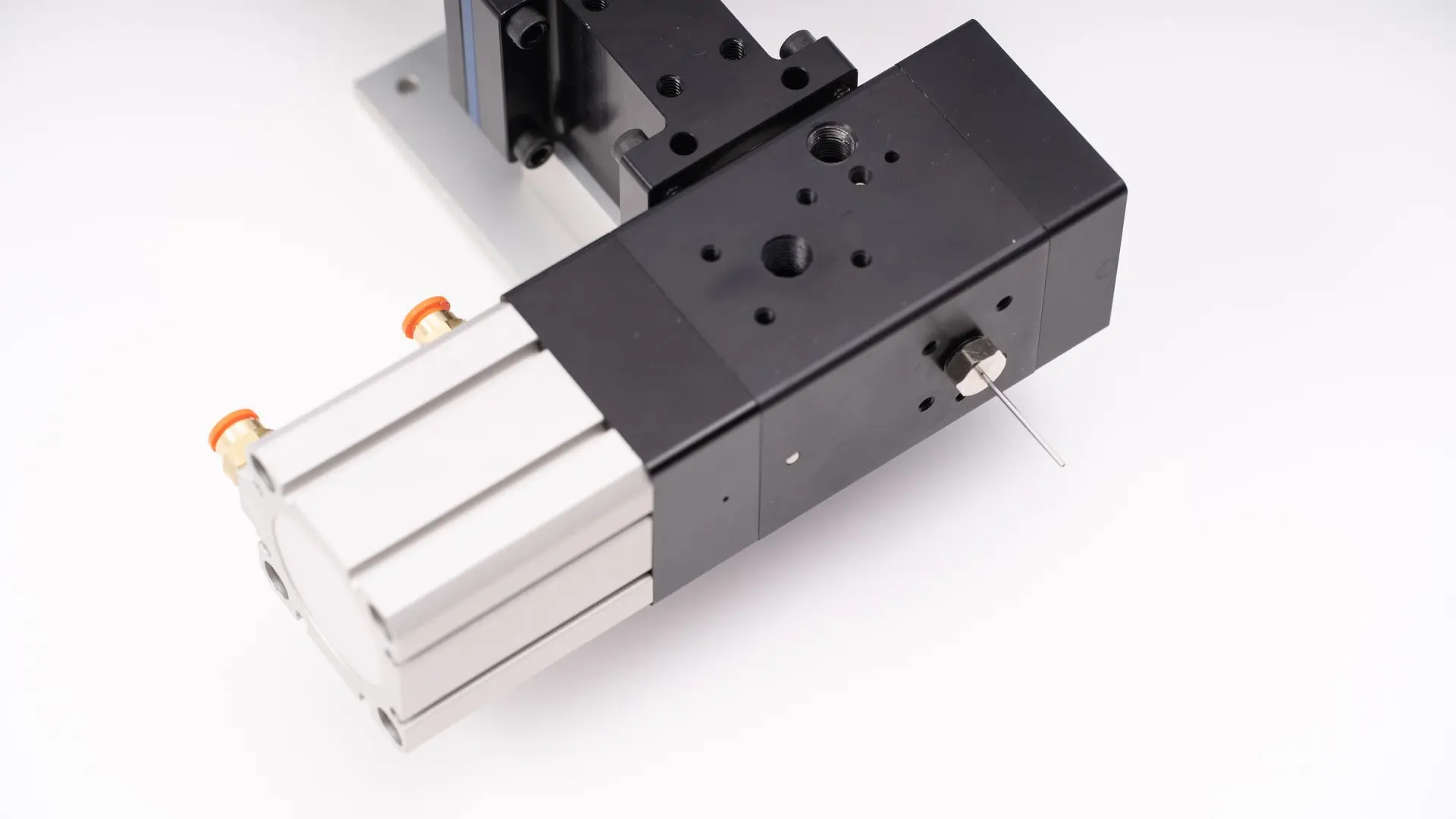

Modular by Design

At DDS, we engineer every system with top-tier components—but real-world variability happens. That’s why the Benchtop Filler’s modular design is built for rapid serviceability. If a component needs attention, simply unplug the old module, plug in the new one, and restore full operation in minutes—minimizing downtime and keeping production moving.

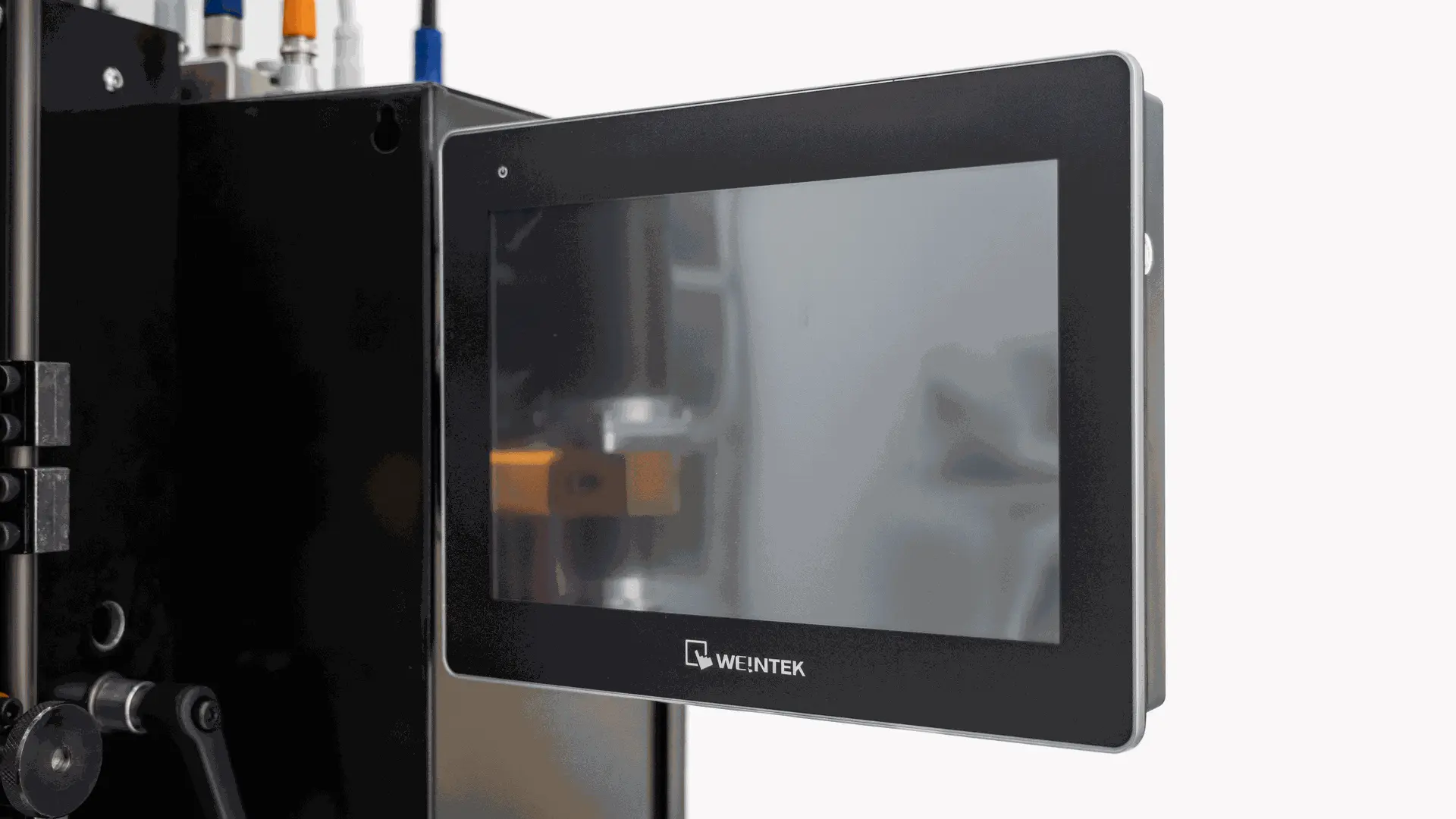

Touchscreen Controls

With its intuitive touchscreen controls, the Benchtop Filler puts calibration, real-time adjustments, and precision settings at your fingertips. Volume-bump functionality ensures each device is filled accurately and consistently, streamlining operations and minimizing waste.

Trusted by Industry Leaders

We’re proud to partner with some of the top names in the industry, helping them scale efficiently and consistently.

Discover the New DDS Benchtop Filler

Fill out the form to get exclusive updates, specs, and early access information